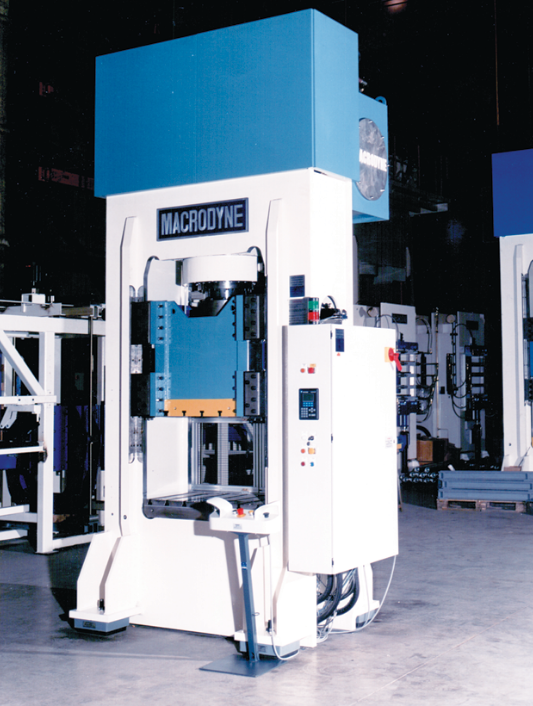

Metalforming Presses

High Performance for High Volume Metalforming Applications

Macrodyne hydraulic metalforming presses are designed with the flexibility and versatility required for various production applications, ranging from large body panels and structural components to individual parts.

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

High Performance for High Volume Metalforming Applications

Macrodyne hydraulic metalforming presses are designed with the flexibility and versatility required for various production applications, ranging from large body panels and structural components to individual parts.

Explore some Metalforming Projects

Don't see one that meets your needs? Get a custom quote for your requirements

Macrodyne Hydraulic Presses Solutions

Macrodyne provides single, double, or triple action hydraulic press based solutions for a wide variety of metalforming processes for many different industries, including automotive, aerospace, consumer product, industrial products, appliances, defense, construction, plumbing, cookware, and medical. A partial list of bulk-forming and sheet metalforming processes our metalforming presses are designed for is listed below:

Heavy-Duty Metalforming Presses for Demanding Production Environments

Macrodyne hydraulic metalforming presses feature heavy, robust press frames with deep, heavy fabricated slides with high guide ratios. The high guide ratio feature results in precision guiding, parallel slide motion, and enhanced eccentric load capacity. These presses can be supplied with standard or custom T-Slot configurations in all sizes and/or a tapped hole pattern to meet the Buyer’s tooling requirements. We offer many innovative solutions for our hydraulic metalforming presses, including a low headroom design. Where facility floor space and/or height restrictions are an issue, the hydraulic power unit can be mounted on the press’s backside. This results in reducing the overall height while eliminating the need for a shallow pit or floor mounted hydraulics, which requires additional floor space.

Full Contingent of Options to Enhance Hydraulic Press Capabilities

Macrodyne hydraulic metalforming presses are available with an extensive list of optional equipment including:

- Single and multi-point cushions

- Light curtain arrangements

- Laser scanners

- Fixed or sliding safety gates

- Work area LED lighting

- Remote diagnostics packages

- Blank holder and punch holder arrangements

- Automatic centralized Grease lubrication systems

- Single and multiple position slide locking arrangements

- Manual and automatic die clamping & lifting packages

- Data acquisition systems and many more.

All presses can be optionally controlled by the industry’s most advanced systems that turn conventional presses into Servo-Hydraulic Presses. This state-of-the-art technology provides you with the steady, reliable force of Hydraulics, with advantages of Servo-controlled programmable motion, ultra-high precision, extremely fast approach/retract speeds, and energy savings.

Enhanced Productivity with Metalforming Presses Automation

Our metalforming presses can be supplied as standalone equipment or as part of a fully automated press line or cell. We can supply the entire press line or cell on a turnkey basis, provide system integration services for buyer-supplied automation and ancillary equipment or provide a provision in the press controls to communicate with automation and other ancillary equipment. Macrodyne’s extensive experience in the supply of automated systems enables us to work closely with the end-user to develop a customized approach, providing any level of involvement in the system integration as desired by the Buyer. This ensures a solution optimized for your specific production requirements while working within your existing budget constraints.

Innovative Die Handling Solutions Available

Macrodyne also offers a line of die handling equipment to serve our hydraulic metalforming presses and any existing presses (mechanical & hydraulic) already installed in our customer’s facilities. Available Macrodyne die handling equipment includes rolling bolsters, “T” tables, die carts, die elevators, die conveyors and cross transfer units, automated die clamping & lifting packages and more. This equipment can be supplied as simple manual equipment to fully automated die storage & retrieval systems.

Effective Solutions for High Impact Blanking Press Operations

For metalforming applications such as punching, blanking or trimming metal parts where excessive reverse forces are generated at the moment of part breakthrough, Macrodyne punching, blanking and trimming presses can be supplied with a shock dampening arrangement. These shock dampening arrangements feature fully programmable powered spindles for shut height adjustment and drastically reduce the shock to the tooling, press structure and hydraulic system. This also allows for faster cycle times, while accommodating off center loads and reducing vibration and noise level at the operator level. If breakthrough forces are not a concern at time of purchase but may be in the future, we can design the press with a provision to accept a shock dampening arrangement in the future. Macrodyne Blanking Press is also the best option for accuracy using high speed to produce precise and cost-effective parts.