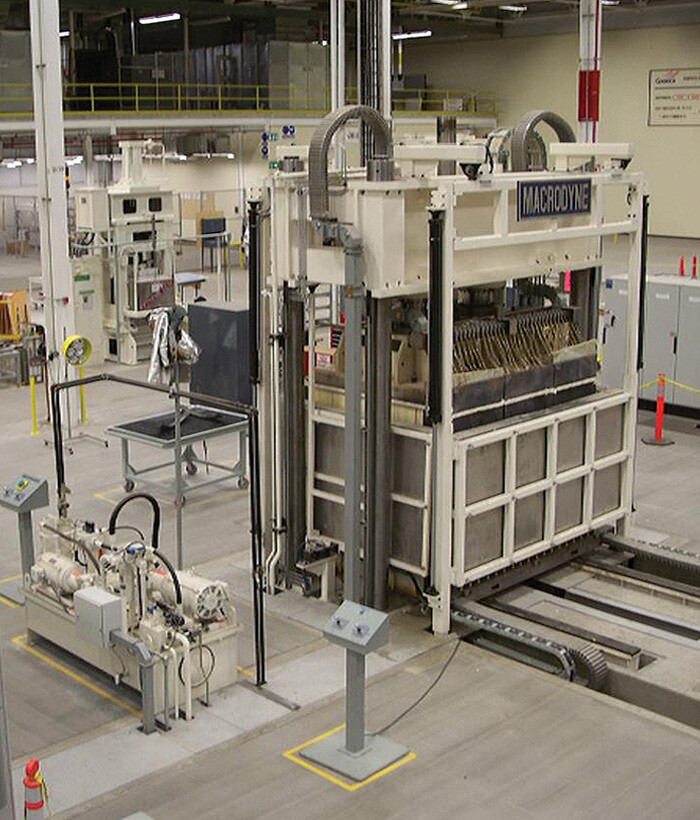

Superplastic Forming Presses

Complex Shaped Component Solutions using Superplastic Forming Presses

Macrodyne manufactures a line of innovative, high-quality SPF presses for titanium, aluminum and nickel alloy aerospace components. Along with traditional superplastic forming (SPF), High-Speed Blow Forming (HSBF), Hot Forming (HF), and Diffusion Bonding (DB) operations are commonly performed on Macrodyne SFP presses. These advanced processes allow manufacturers to produce a wide array of parts with complex geometries that cannot be formed using any other technology.

Traditional SPF and even HSBF is becoming obsolete after the introduction of GO-SPF (Gas Oscillation SPF), a Disruptive New Technology for Superplastic Forming.

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Complex Shaped Component Solutions using Superplastic Forming Presses

Macrodyne manufactures a line of innovative, high-quality SPF presses for titanium, aluminum and nickel alloy aerospace components. Along with traditional superplastic forming (SPF), High-Speed Blow Forming (HSBF), Hot Forming (HF), and Diffusion Bonding (DB) operations are commonly performed on Macrodyne SFP presses. These advanced processes allow manufacturers to produce a wide array of parts with complex geometries that cannot be formed using any other technology.

Traditional SPF and even HSBF is becoming obsolete after the introduction of GO-SPF (Gas Oscillation SPF), a Disruptive New Technology for Superplastic Forming.

Explore some Superplastic Forming Projects

Don't see one that meets your needs? Get a custom quote for your requirements

Disruptive New Technology for Superplastic Forming

Gas Oscillation Enhanced SPF: The Next Generation of Superplastic Forming

Macrodyne and AEM Power Systems are collaborating to integrate gas oscillation technology into Macrodyne’s Superplastic Forming Presses, to significantly improve the formability of various metallic alloys.

The Gas Oscillation Forming Technology for Superplastic Blow Forming is a disruptive advancement in the SPF process that provides significant improvements in the formability of alloy sheets. This patented new technology pushes past the boundaries of conventional superplastic forming allowing for dramatically more geometrically complex parts to be formed with higher quality and at lower costs.

Macrodyne SPF press with gas oscillation forming system can be used on Aluminum, Magnesium, Titanium, and possibly other alloys, to benefit the aerospace, automotive, defense, medical, architectural, marine sectors, and much more, with custom-designed solutions for any application.

Learn More: GO SPF: The Next Generation of Superplastic Forming

Process Specific Features Standard on Macrodyne Hydraulic SPF Presses

Standard features of Macrodyne superplastic forming presses include:

- Precise and uniform multi-zone temperature control

- Specialized plunger guide arrangements

- Precision gas management systems

- High-speed data acquisition systems

- Highly efficient heat shields & ceramic insulation

- Heated platens

- Cooling platens

- Rolling bolsters

- Remote diagnostics

Macrodyne Superplastic Forming Press Solutions

Our modern superplastic forming presses feature the same high level of quality present in all Macrodyne hydraulic presses and are capable of both superplastic forming and hot forming (hot sizing) operations. These presses provide the ability to form complex shaped titanium, aluminum and nickel alloy components such as engine blades using inert gas forming at high temperatures up to 1800 degrees Fahrenheit.

Accuracy and Repeatability of Argon Gas Pressures Coupled with Multi-Zone Temperature Control

Accurate and repeatable argon gas pressures and multi-zone temperature control are critical elements of a successful superplastic forming operation. These process variables are easily managed using Macrodyne’s proprietary flexible and repeatable superplastic forming press control system. These presses are available in standard configurations or can be customized to suit the Buyer’s specific requirements, regardless of the size or complexity.

Learn more about the Superplastic Forming.

Contact us about your hydraulic press needs